Description

Orisun multi-blenders offer a variety of capacities to handle a wide variety

of applications. Drawing on our nearly 20 years of practical experience,

multi-shaft mixers are available in laboratory, pilot scale and full production

capacity, offering a flexible range of shear levels to accommodate varying

product viscosities and homogenization requirements.

Features:

Suitable for adhesive, sealant, MS polymer, Lithuim Battery slurry, solder

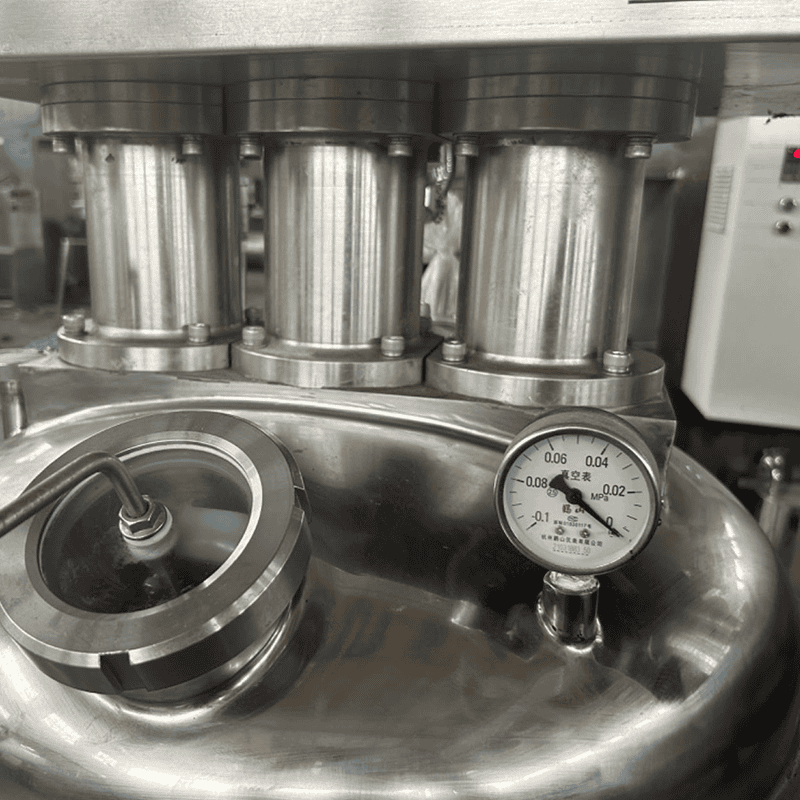

paste with viscosity 10,0000~1,000,000cps.The working capacity is from 2L to

1300L.Extreme vacuum up to -0.1 MPA for high efficiency of defoaming.

Orisun Triple Shaft Mixer Features

Suitable for adhesive, sealant, MS polymer, Lithuim Battery slurry, solder

paste with viscosity 10,0000~1,000,000cps.

The working capacity is from 2L to 1300L.

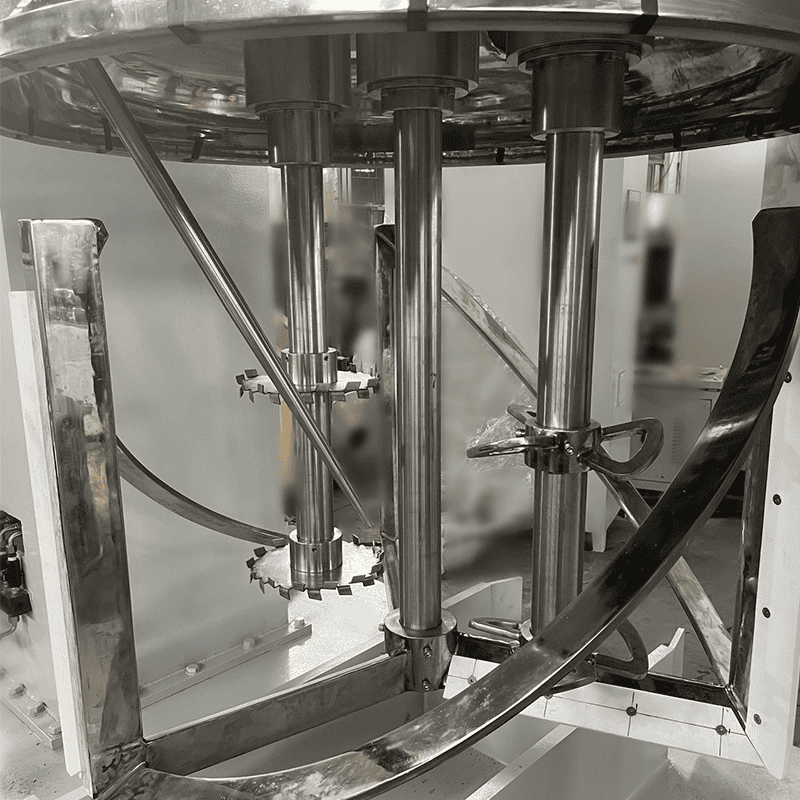

The shape of stirring paddle can be designed according to the material

characteristics, commonly used are dispersing disk, butterfly stirring, dauer

stirring, homogenizing stirring and so on.

The wall scraping agitator is designed to fit into the mixing drum to ensure

no material sticking to the inner wall of the mixing drum.

Extreme vacuum up to -0.1 MPA for high efficiency of defoaming.

Material 304 and 316 are optional.

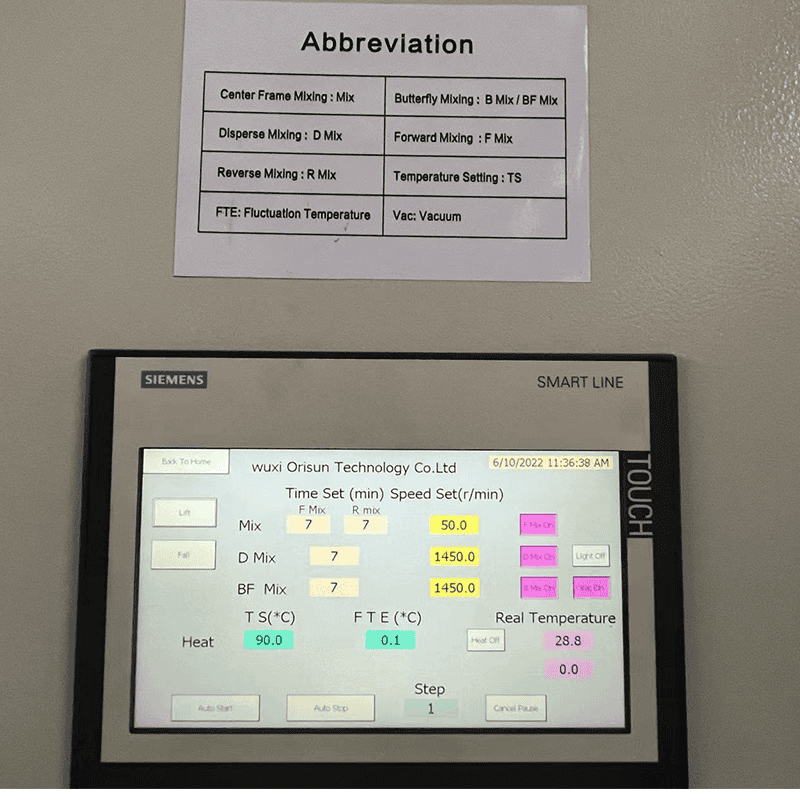

The control mode can be button operation or PLC touch screen mode.

Our product stands out in the market with its advanced features designed to

improve your productivity and reduce operational costs.

Vacuum rated mixer/hood combination.

Air sweep blades with sidewall scrapers.

High speed blades available with dual mixing blade option.

Rotor stator or emulsion head available.

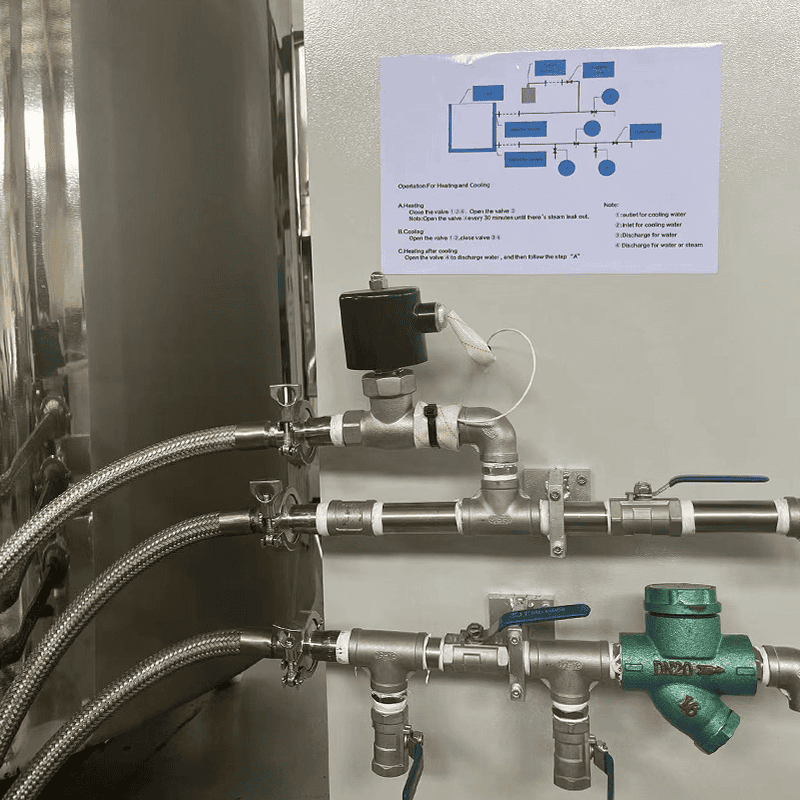

Jacketed mixing tank for heating/cooling.

Specification

Triple Shaft Mixer Technical Data

Get specific information on the specifications and parameters of our

equipment.

| Model | Tank Volume | First Shaft (Frame Mixer) | Second Shaft (High Speed Disperse) | Third Shaft (High speed Disperse / Homogenizer) | Max Vacuum Pressure | Main Tank Size (L*W*H)MM |

| TJR-2 | 2 | 0.75 | 1 | 1 | -0.09MPA | 880*550*1430 |

| TJR-5 | 6.5 | 1.5 | 2 | 2 | -0.09MPA | 880*650*1430 |

| TJR-10 | 12.5 | 1.5 | 2 | 2 | -0.09MPA | 880*750*1430 |

| TJR-20 | 25 | 1.5 | 2 | 2 | -0.09MPA | 880*850*1430 |

| TJR-30 | 30 | 1.5 | 3 | 3 | -0.09MPA | 1400*1600*(1900-2400) |

| TJR-50 | 50 | 2 | 3 | 3 | -0.09MPA | 1450*1600*(1950-2400) |

| TJR-100 | 100 | 3 | 4 | 4 | -0.09MPA | 1750*650*(2150-2850) |

| TJR-150 | 150 | 4 | 6 | 6 | -0.09MPA | -1900*780*(2380-3000) |

| TJR-250 | 250 | 4 | 8 | 8 | -0.09MPA | 1850*1105*(2480-3480) |

| TJR-350 | 350 | 4 | 10 | 10 | -0.09MPA | 2000*1350*(2750-3850) |

| TJR-500 | 500 | 11 | 15 | 15 | -0.09MPA | 2400*1250*(3130-4460) |

| TJR-650 | 650 | 11 | 20 | 20 | -0.09MPA | 2400*1250*(3130-4460) |

| TJR-850 | 850 | 15 | 30 | 30 | -0.09MPA | 2650*1450*(3350-4750 |

| TJR-1000 | 1000 | 15 | 40 | 40 | -0.09MPA | 2700*1350*(3230-4700) |

| TJR-1300 | 1300 | 20 | 45 | 45 | -0.09MPA | 2800*1500*(2950-4560) |

Reviews

There are no reviews yet.