Description

General Introduction:

An open-mouth bagger is a type of packaging machine that automatically fills

and seals pre-made, open-mouth bags. The bags can be made of various materials

such as paper, plastic, or woven polypropylene, and are suitable for a range of

products including powders, granules, and pellets. In an open-mouth bagging

system, a device holds each bag open, and the product is dispensed into the bag.

Once the bag filling is complete, it is sealed, typically by heat sealing,

stitching, or gluing to prevent any spillage or contamination. Open-mouth

bagging systems are widely used in industries such as agriculture, food

processing, chemicals, and construction to streamline packaging processes and

increase efficiency.

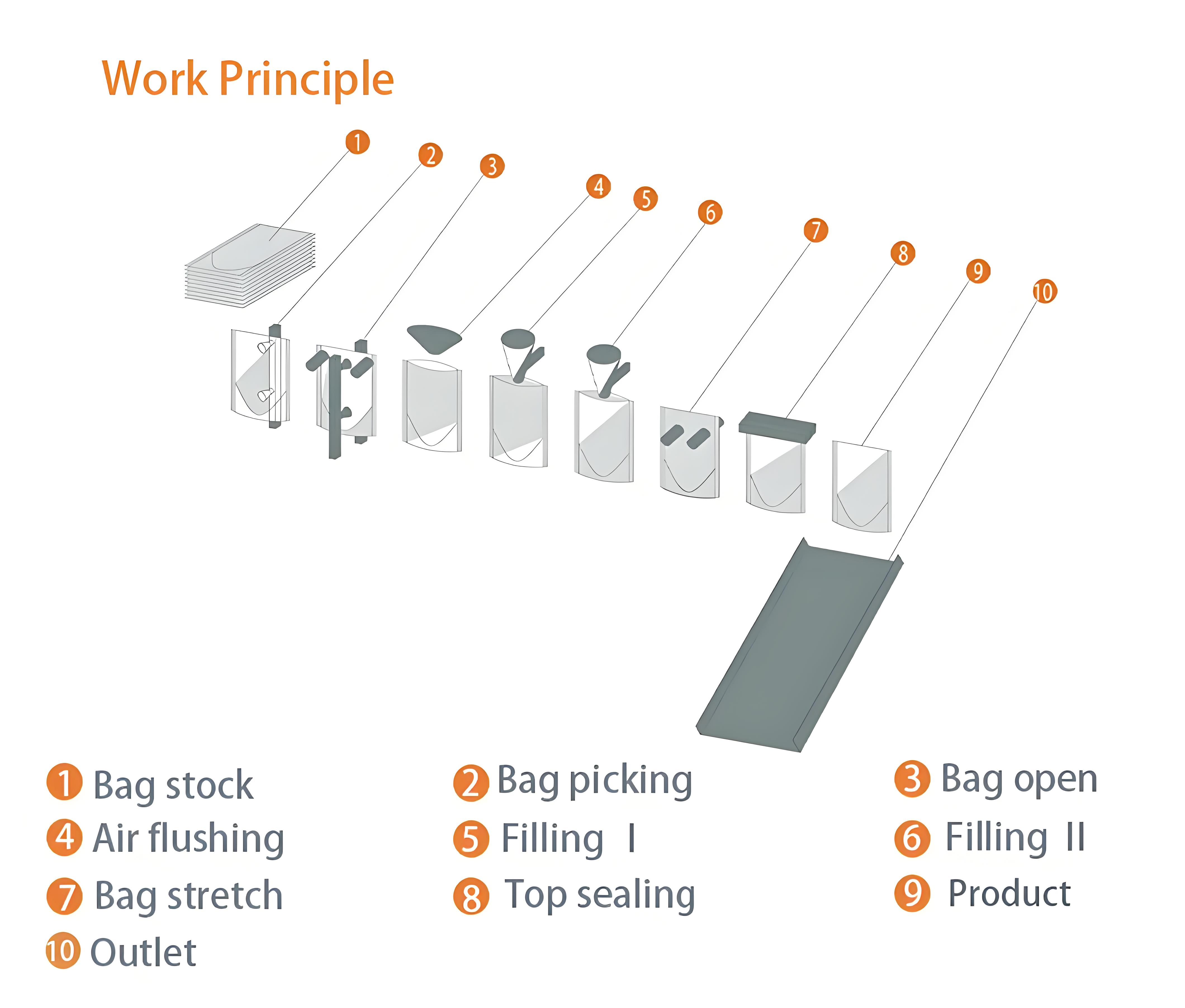

Working Process:

1. Pre-place Empty Bags: Place 2~3 stacks of empty bags at the same time to

provide bags for the packer.

2.Take an Empty bag: The bag sucking mechanism sucks the bottom of the bag

with negative pressure, while the roller-up type bag transmission structure

flattens the bag mouth and transmits it to the bag opening station.

3.Open Empty bag: The bag opening mechanism simultaneously sucks the positive

and negative sides of the bag mouth with negative pressure. The negative

pressure sucks the bag mouth and lifts it, and then the “insert knives”

structure located on both sides of the material discharge port is inserted into

the bag mouth by shaft rotation and spread to both sides .

4.Supply Empty bag: Transfer the empty bag to the bag clamping mechanism by

lifting up the knife arm to complete the bag supplying operation. The bag

clamping mechanism clamps both sides of the bag to prevent dust from

overflowing.

5.Material Filling: The bag clamping detection device ensures the reliability

of the bag supplying. After the detection is completed, the PLC will give a

signal to the automatic weighing unit, then the material in the weighing unit

will be discharged into the packaging bag. During the filling process, perform

bottom vibration operation. At the same time, through the external dust removal

interface, the dust formed by the material is pumped away in the discharge

process.

6.Holding bag and Heat Sealing: After the material filling is completed, the

bag mouth is clamped horizontally through the bag-holding conveying mechanism,

then the bag is horizontally conveyed to the guide entry mechanism, and the bag

is conveyed to the heat sealing (Sewing) station for automatic heat sealing

(Sewing).

Product Feature:

1. Automatic adjustments for quick product and bag changeovers

2. Total bag top control

3. Optimized dust control

4. PLC controlled with user-friendly human machine interfaces (HMI)

5. Easy clean and easy maintenance configurations

6. Compact design ideal for restricted packaging rooms

7. Fully integrated gross or nett weighing system

Specifications:

|

Model Series |

DSD-25L |

DSD-50S |

DSD-50H |

|

Packable Products |

Granules |

Granules |

Granules |

|

Empty Bag Size |

L(500-750mm), W(320-420mm) |

L(750~900mm)×W(400~500mm), L(850~1000mm)×W(500~650mm) |

|

|

Packaging Weight |

10-25 kg/bag |

10~50KG/bag |

|

|

Packaging Speed |

100~150 bags/h |

300~500bags/h |

500~700bags/h |

|

Bag Types |

PE bags/ aluminum foil bags/ woven bags/ paper bags/ paper-plastic |

||

FAQ:

1. What is an open-mouth bag?

An open mouth bag has one open end through which product is emptied through a

large, throated spout. Open mouth bags package virtually any type of product and

are filled with specialized filling machines. Filling and sealing open-mouth

bags is a two-step process. The open end of an empty, open mouth bag is placed

under the filling spout of an open mouth bag filler. The spout is clamped inside

the bag’s open to prevent product spillage. After the bag is filled, it is

sealed or closed, with a hot melt glue sealer, plastic bag sealer, or bag sewing

machine. Open mouth bags are commonly used to contain and transport dry powders

and granular products like food, chemicals, seeds, grains, fertilizers, and

landscaping products. Open mouth bags are constructed of a variety of materials

including paper, plastic film, and plastic woven mesh.

2.What’s the difference between semi-automatic and fully automatic

bagger?

§ A fully automatic packaging system is best for high speeds and minimal

human interaction, in situations that produce many products with relatively low

variation. A fully automated line includes tools to feed the product to the

system, a scale, and an automatic bagging machine. Automated systems are known

for accuracy and consistency but require a large upfront investment.

§ A semi-automatic packaging system requires reliance on human labor, using

an automated scale to weigh the product, but a human technician to dispense the

product into bags and seal them. Semi-automatic packaging lines are a good

first-solution, as individual machinery can be integrated later to create a

fully automated system. Semi-automatic packaging lines are less expensive, but

also less accurate and slower than fully automated systems.

3. Can one automatic bagger machine handle different bags style, sizes, and

products?

Adjusting an automatic bagger machine to accommodate different bags is called

changeover, and is usually a fast process. Consider automating different parts

of the process to further simplify your production line. If you find you need a

system with further automation, you may want to invest in more automated

equipment.

4. What are automatic bagger fillers you need ?

Automatic bagging machines measure quantities of product into the packaging

machine to be dispensed into the bags. Fillers usually sit above or off to the

side of the packaging machine. An automatic bagging machine is best for

companies hoping to incorporate more uniformity and ease of production into

their environment.

Reviews

There are no reviews yet.