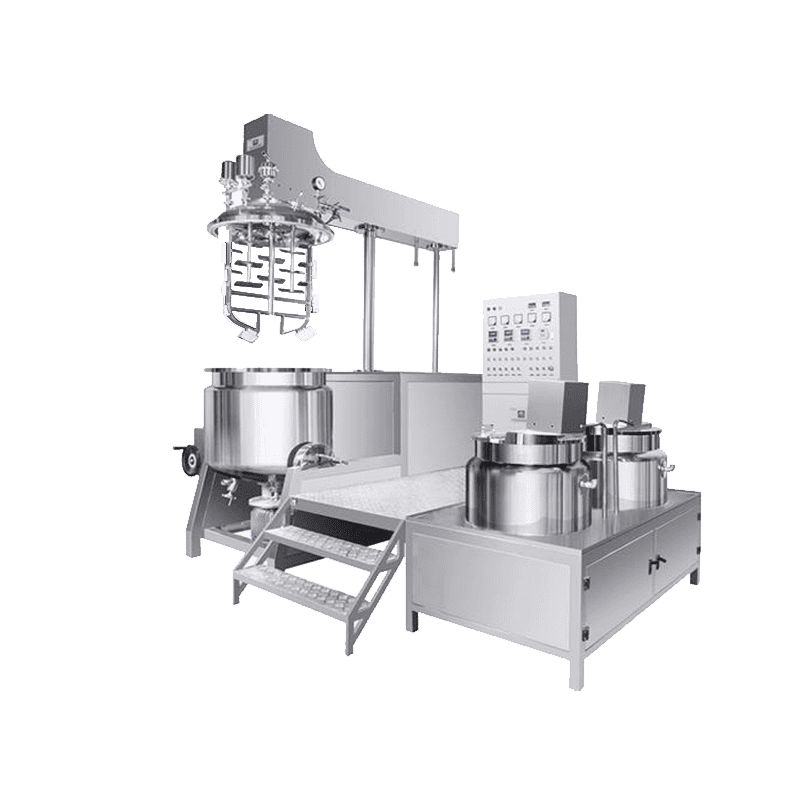

Description

Our company prides itself on our cutting edge technology and our commitment

to providing exceptional service to our customers. With our nearly 20 years of

experience, our bottom emulsifier mixers are designed to be reliable, efficient

and effective in all mixing operations, ensuring the highest quality in your

production process.

Features:

Suitable for creams and lotions with viscosity of 10,000~200,000cps.

Working capacity from 30L to 100L.

Ultimate vacuum up to -0.1 MPA for efficient defoaming.

Orisun Bottom Vacuum Emulsifier Homogenizer Features

Suitable for creams ,lotion , ointment , lotion and sauce with viscosity of

10,000~200,000cps.

Working capacity from 30L to 3000L.

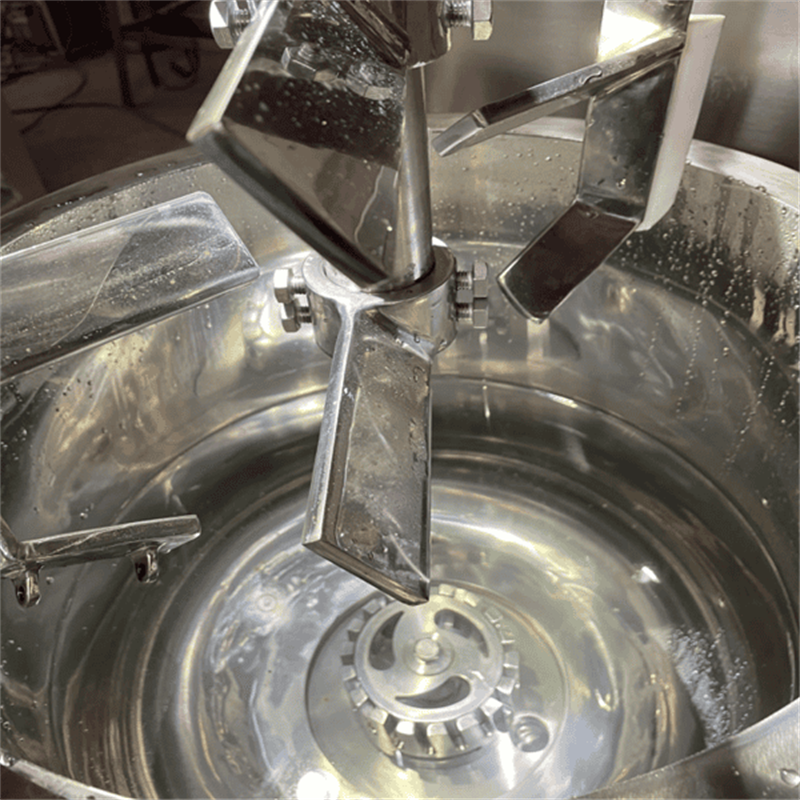

Reverse mixing system with center mixing shaft and wall scraping mixing.

Equipped with a discharge valve at the bottom of the tank, which is

convenient for draining the washing water.

Ultimate vacuum up to -0.1 MPA for efficient defoaming.

water jacket for heating and cooling , water , steam , conductive oil could

be used as medium

Discharging could be both by bottom valve or tilting the tank

Bottom Vacuum Emulsifier Homogenizer Mixer Details

Bottom emulsifying mixers are also known as under emulsifying mixers. That

is, the homogenizing rotor is installed at the bottom of the tank. The main

structure and mixing method is the same as ZJR series upper homogenizing and

emulsifying mixer.

The emulsifying mixer lifts automatically and cleans the tank thoroughly.

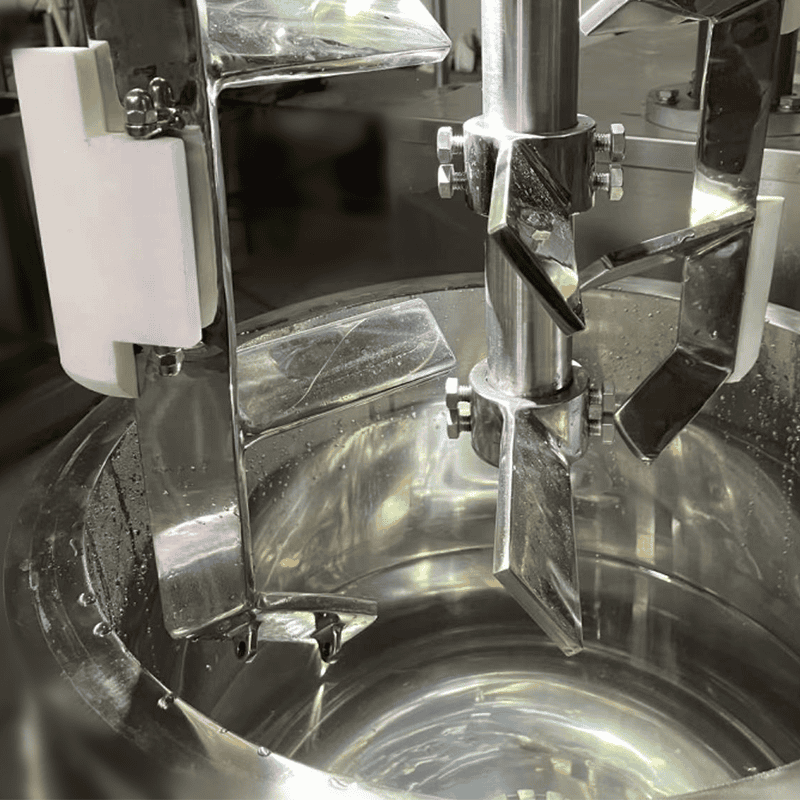

Stirring paddles are suitable for various complex recipes to achieve

optimized results. PTFE scraper caters to the stirred tank and scrapes away the

sticky material from the pot wall.

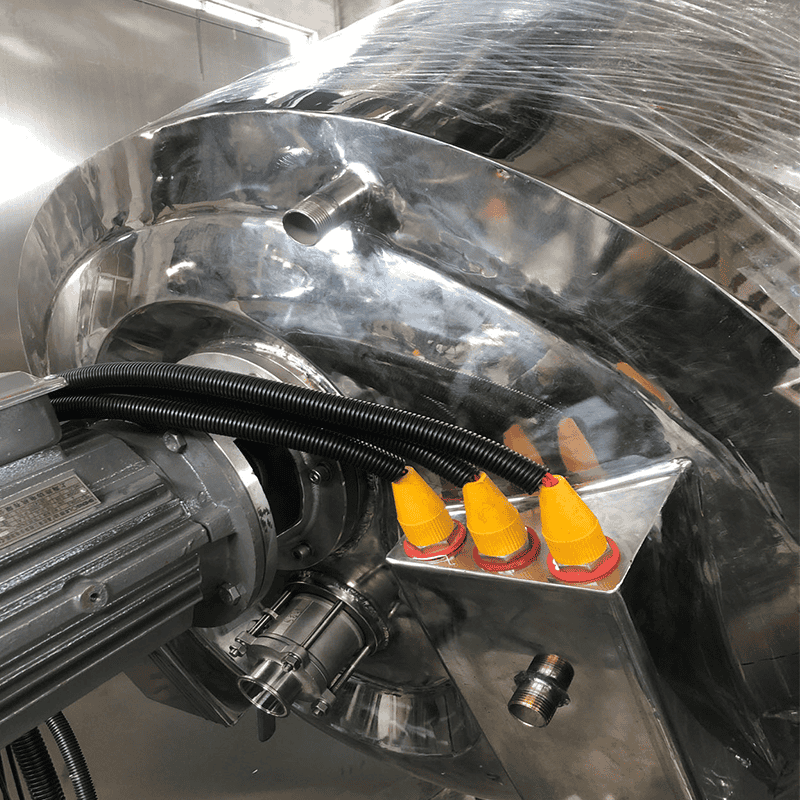

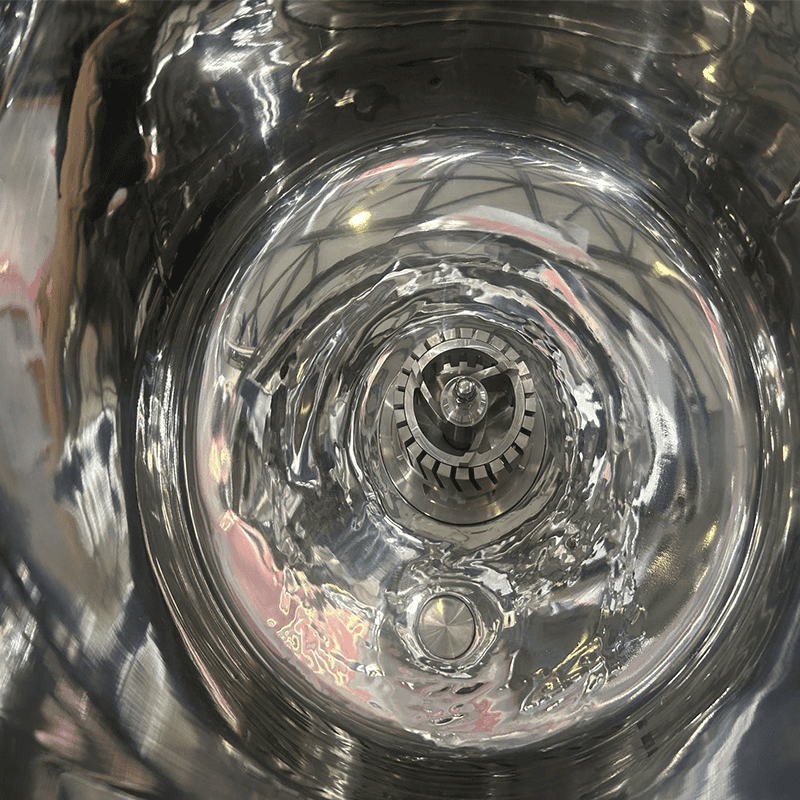

Homogenizer is installed at the bottom of the boiler to make the motor power

boost more thoroughly and powerfully. In a small amount of production, it can

give full play to homogenization.

The main tank bottom homogenizing hydraulic emulsifying mixer and material

contact parts are made of export USU 316 stainless steel.

Realize high efficiency liquid cutting, friction, centrifugal, ensure cream

fine and smooth. And the surface of the tank and pipe is polished by 300 mesh

mirror (sanitary grade), in line with the daily chemical and GMP standards.

Specification

Bottom Vacuum Emulsifier Homogenizer Technical Data

Get specific information on the specifications and parameters of our

equipment.

| Volume | 100L | 150L | 300L | 500L |

| Vacuum pressure | -0.09 M pa | -0.09 M pa | -0.09 M pa | -0.09 M pa |

| Temperature | ≤120 ℃ | ≤120 ℃ | ≤120 ℃ | ≤120 ℃ |

| Speed of Scraping Plate Blender | 0-86 r/min | 0-86 r/min | 0-86 r/min | 0-86 r/min |

| Speed of Homogenizer | 0-3500r/min | 0-3500r/min | 0-3500r/min | 0-3500r/min |

| Voltage | 50Hz 380V±10%-15% | 50Hz 380V±10%-15% | 50Hz 380V±10%-15% | 50Hz 380V±10%-15% |

| Volume of water pot | 80 L | 120 L | 240 L | 400 L |

| Volume of oil pot | 50 L | 75 L | 150 L | 250 L |

Reviews

There are no reviews yet.