Description

With just three machines and 100 square meters of space, Haining Zhengli

Rubber & Plastic Factory began manufacturing custom rubber parts on January

1st, 1993. Founder Yuezhong Wang and his family built the company from the

ground up on a foundation of commitment, hard work, quality service &

products, and family values which are "To Be Honest, To Do Best".

Shortly after its establishment, during a period of growth, ZLR encountered a

significant challenge as the founder's father was diagnosed with cancer. Mr.

Wang utilized all of his resources to treat his father but unfortunately, he

couldn't save him. Mr. Wang continued to pursue excellence, following his

father’s legacy, despite the painful experience. In the ensuing decades, ZLR

continued to grow and expanded further in Haining, Zhejiang in 2008, with the

construction of a 1,500-square-meter facility.

Key milestones include establishing a materials department in 1999, beginning

online sales in 2003, obtaining ISO 9001 certification in 2012, and starting

plastic production in 2016.

To provide much-needed support for this rapidly growing enterprise, Yuezhong

Wang’s son, Andong Wang, joined the factory to support its growth in marketing

after completing his studies in Massachusetts in 2016. The factory adapts to

changing market conditions, seeks new opportunities and is committed to

providing high-quality rubber products and services.

After 30 years, five locations, and three generations of hard work, ZLR

successfully maintained the core values established in 1993 with a full

commitment to employees, customers, and the community.

Outstanding Features of Zhengli's Sealing Rings

Zhengli's Sealing Rings are engineered with precision and designed to deliver exceptional performance in various industrial applications. These sealing rings are known for their:

-

Durability: Crafted from high-quality materials, Zhengli's sealing rings are built to withstand the test of time and harsh operating conditions.

-

Reliability: They provide a consistent seal, ensuring that there are no leaks or failures, even under pressure.

-

Customizability: Zhengli offers a wide range of customization options, allowing these sealing rings to fit specific application needs perfectly.

-

Versatility: Suitable for use in a variety of sectors, including automotive, aerospace, and medical industries, Zhengli's sealing rings are a versatile solution for many sealing challenges.

Applications of Zhengli's Sealing Rings

The versatility of Zhengli's sealing rings makes them a popular choice across a broad spectrum of applications:

-

Automotive Industry: Used in engines and transmissions to seal against oil and other fluids, ensuring efficient performance.

-

Aerospace: Vital in sealing aircraft engines and other critical components where reliability is paramount.

-

Medical Devices: Zhengli's sealing rings are used in various medical equipment where sterility and safety are of utmost importance.

-

Industrial Machinery: Employed in a wide range of machinery to prevent fluid leakage and maintain optimal operating conditions.

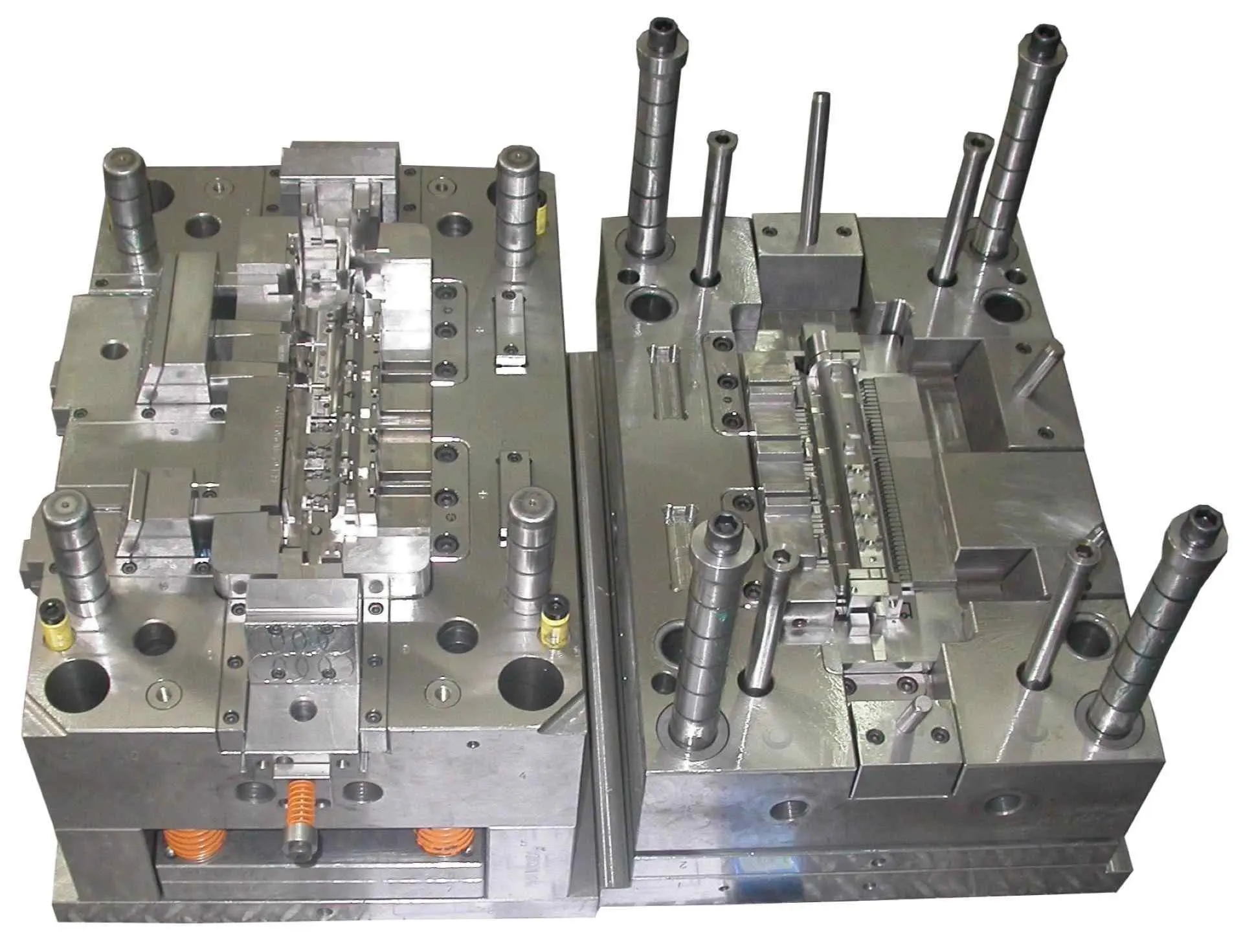

Manufacturing Process of Zhengli's Sealing Rings

Zhengli takes pride in its meticulous manufacturing process, which ensures that each sealing ring meets the highest standards of quality:

-

Material Selection: The process begins with the careful selection of materials that possess the necessary properties for the intended application.

-

Design and Engineering: Utilizing state-of-the-art design software, Zhengli's engineers create detailed blueprints for each sealing ring, taking into account factors such as size, shape, and material composition.

-

Molding: Advanced molding techniques are employed to shape the sealing rings with high precision. This step is critical in ensuring that the final product meets the exact specifications required.

-

Quality Control: Throughout the manufacturing process, multiple quality checks are conducted to ensure consistency and adherence to the highest standards. This includes dimensional checks, material testing, and functional testing.

-

Finishing: Post-molding, the sealing rings undergo a series of finishing processes to refine their surface and ensure a perfect fit and finish.

-

Packaging and Shipping: Finally, the sealing rings are carefully packaged to protect them from damage during transit and shipped to customers worldwide.

Zhengli's commitment to excellence is evident in every step of the manufacturing process, from the initial design to the final product. This dedication to quality and precision is what makes Zhengli's sealing rings a trusted choice for industries around the globe.

Reviews

There are no reviews yet.