Description

Technical Parameter

|

Max. workpiece diameter |

mm |

250 |

|

Max. rotation angle |

° |

±45 |

|

CNC Control System |

Siemens |

|

|

Language |

Chinese, English, Russian,Spanish, Portuguese |

Machine Feature

This series of high-speed and high-efficiency CNC gear hobbing machine adopts

the principle of generation method to realize the gear hobbing. The main castings

of the CNC gear hobbing machine are designed with double-wall and high-rib plate

structure, and through finite element analysis, it can not only ensure the

overall rigidity of the CNC gear hobbing machine but also take into account the

stability of the CNC gear hobbing machine. The large column of CNC gear hobbing

machine moves to complete the radial feed movement, the electrical control box

of the machine tool is located at the rear; the hydraulic pressure, lubrication

and cooling of the machine tool are completely independent subsystems. GLT /

GLTM CNC gear hobbing machine received unanimous praise from Chinese and

international customers. Below are the main features of the machine:

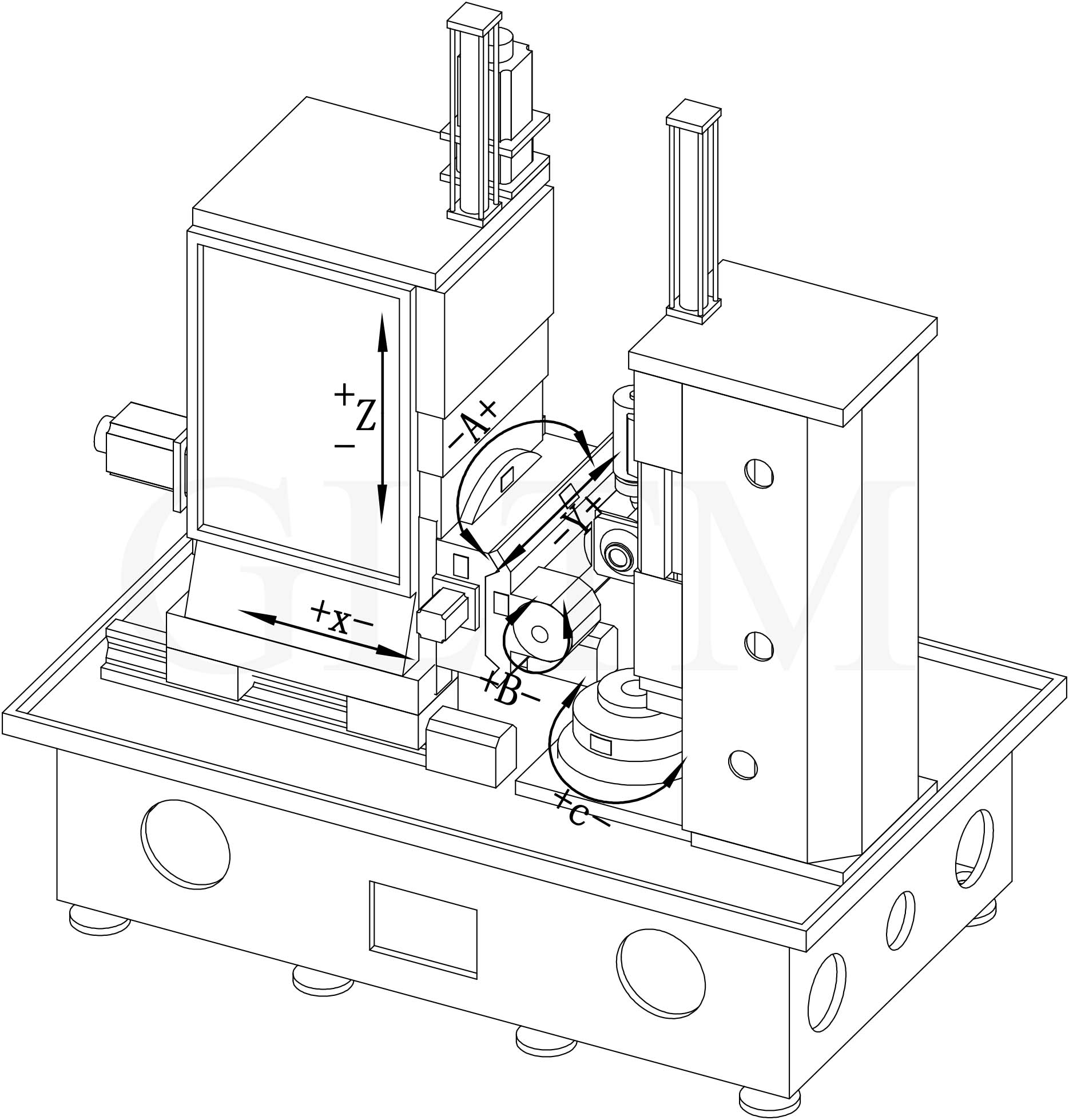

• The CNC gear hobbing machine has 2 configurations of 6-axis and 7-axis for

option.

• The tool holder adopts hydraulic pressure to automatically fasten and

release, which is convenient for users to change tools and shortens the time for

tool adjustment.

• The X and Z axes of CNC gear hobbing machine adopt high-rigidity guide

rails, which make the guide rails of the CNC gear hobbing machine maintain

long-term accuracy and long service life, and facilitate later maintenance.

• The C-axis of CNC gear hobbing Machine is driven by a high-precision motor,

which ensures the indexing accuracy of the worktable and provides strong cutting

force for gear hobbing.

• The Y-axis of CNC gear hobbing Machine is directly driven by a servo motor

to ensure the precision of the tool shifting and prolong the service life of the

hobbing cutterl, while ensuring the overall cutting rigidity of the CNC gear

hobbing machine.

• The guide rail of tailstock of CNC gear hobbing machine is a high-precision

linear or rigid rail, and is equipped with an oil cylinder to drive the

tailstock movement, ensuring the movement accuracy of the tailstock and the

convenience of CNC gear hobbing machine adjustment.

• The processing area of CNC gear hobbing machine is equipped with stainless

steel inner protection, which completely separates the processing area and

facilitates chip removal.

• Precise auto tool setting device for option to achieve second time gear

hobbing for the hardening gear surface.

• Equipped with a rotating top tailstock center, avoiding the wear of the

center hole of workpiece, and enhancing the rotation accuracy of the tailstock

center.

• Automatic workpeice loading and unloading system, and automatic chamfer

machine connection are available for option for CNC gear hobbing machine.

Standard Configuration

CNC system (Siemens)

Built-in gear hobbing program package

Electrical cabinet

Electric cabinet air conditioner

Hydraulic system

Wet cutting cooling system for gear hobbing machine

Centralized quantitative lubrication system

Tool holder

Shock-proof adjustment pad

Tailstock center

Clamp fixture base

Automatic fixture hydraulic system

Magnetic chip conveyor

Steel chip trolley

Oil mist collector

Deburring device

Tri-Color signal light

Working light

Flushing gun

Manual pulse generator

Instruction manual

Optional

CNC system (FUNUC)

Dry Cutting with air cooling

Auto tool setting device

Auto door

Grating scale

Workpiece auto loading system

Clamping fixture

Hobbing cutter

Power off safety stop function

Voltage stabilizer

Automatic chamfer machine connection with gear hobbing machine

Production Case

Why Choose Us

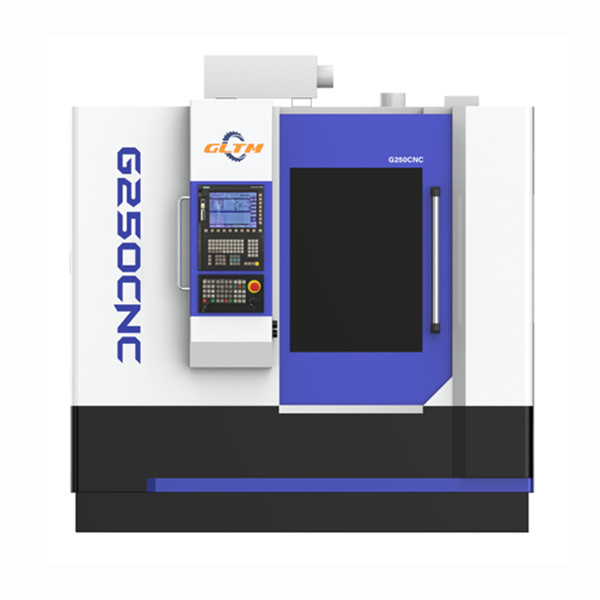

As a reliable Chinese manufacturer with 20 years of expertise in

high-precision CNC gear hobbing machines, our factory guarantees world-class

performance and reliability. Our CNC gear hobbing machines integrate

world-renowned branded components to ensure exceptional durability and

cutting-edge functionality, achieving maximum accuracy up to Class 5 – 6

validated by pre-acceptance testing at our facility. With a diverse range of CNC

gear hobbing machine models (including G80CNC, G100-B, G160, G200, G260, G300,

G350, G400, G500, G600, G800, G1000, G1200, G1500, G2000), we cater to varied

industrial needs while offering optional automatic workpiece loaders for

enhanced efficiency. Our CNC gear hobbing machine compliant with European

geometric standards and CE-certified, our gear hobbing machines prioritize

safety and precision. We ensure fast global delivery with end-to-end logistics

support and provide 365-day multilingual service to guarantee seamless

operations. Our commitment to transparency includes factory audits, reinforcing

our reputation as a dependable partner for CNC gear hobbing solutions

worldwide.

Reviews

There are no reviews yet.